Screw splitter: here’s everything you need to know

Also known as a conical screw splitter, this is a mechanical device designed to split wood logs safely and efficiently. Unlike traditional manual methods, which require physical force and can be dangerous, this tool uses a screw system that exerts gradual and steady pressure on the wood, cleaving it precisely.

Facilitated by its conical shape that facilitates screwing and drilling, it is most useful for breaking large woody material and logs. It can also be used for moving large logs that would otherwise be impossible to move by hand. It meets a variety of needs and is used in both amateur and professional settings.

It finds its main use in the following scenarios:

– forestry

– timber industry and recycling

– woodworking sites

– green waste remediation and maintenance

– green waste management

– sawmills

– production and recycling of branches and agricultural and forestry waste

The Operation

As is easy to guess from the name, the screw splitter is based on a conical screw, which is inserted into the log of wood. When the screw begins to turn, thanks to the action of a motor or an Auger, its conical shape allows it to penetrate the wood with ease. As the screw advances, the pressure exerted by its coils pushes the wood fibers outward, causing a gradual but firm split in the log. This process significantly reduces the physical effort required compared to manual splitting with an axe, making the work faster and safer. In addition, adjusting the speed of screw rotation allows the operation to be adapted to different types of wood, optimizing the effectiveness of splitting.

How to Recognize a Quality Product

Recognizing a quality conical screw splitter versus a low-quality one is crucial. In fact, it is very important to ensure a durable and efficient tool, and even more important to ensure safety and functionality while working. A quality product is distinguished first and foremost by the materials used: tapered screws made of hardened or heat-treated steel are more resistant to wear and tear and breakage. Ease of use and maintenance, an element often underestimated, is also an indicator of quality: an ergonomic design and the ability to easily replace worn parts extend the life of the product and improve its operability. Finally, certifications of compliance with safety regulations offer further confirmation of product reliability and quality. Avoiding overly cheap products, which often skimp on materials and safety, is crucial to avoiding inconvenience and getting a tool that can really make work easier.

The QM screw splitter

All QM models have the centering tip fabricated from replaceable hardened steel, an aspect that enables this tool to be of excellent quality in operational terms and to have considerable longevity.

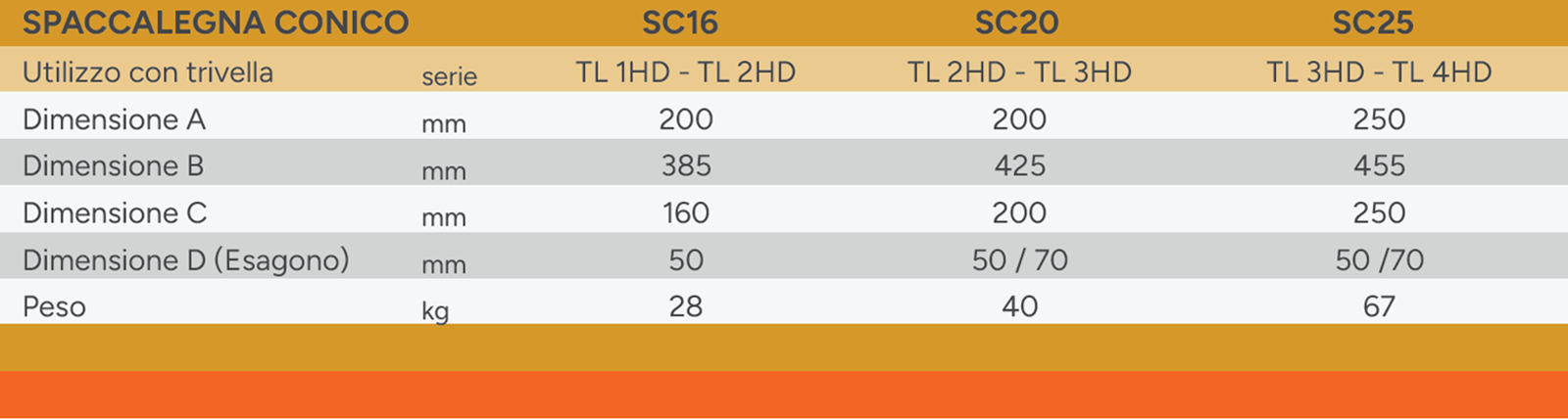

The qm screw splitter employs significant radial forces and loads. The oscillations and stresses during processing subject the tool to intense stress; therefore, use with the HD Auger is recommended. Available in three different models that we highlight by size and weight in the following table:

Dimensions refer to respectively:

– to the capital to the base of the conical tip

– to the length of the drill cone

– to the diameter of the conical base

Finally, the size of the hexagon corresponds to the size of the plug hole with the TL HD TRIVELLA.

Installation and useful tips

The connection is very simple. Follow the following actions slavishly:

– Lubricate the inside of the hexagonal bushing of the Log Splitter and the hexagonal connector of the Auger

– engage the attachment

– insert and lock the security screw.

When finished:

– disconnect the tool from the Auger

– lubricate the inside of the hexagonal bushing

– place the tool in a safe place protected from weather and

For proper use of the QM Log Splitter we recommend:

– use the tool only with woody material

– during handling, partially screw the wedge into the center of the log and not sideways

– drill until the log breaks without forcing in any direction

– avoid forcing the log against the operating machine or other rigid parts

– do not use the attachment for excavation, breaking roots or plants anchored in the ground, and in construction demolition

– do not use on knots, stones or objects embedded in the plant

Strengths

Strengths

Among the most important things is the total absence of maintenance.

Other relevant factors are:

– enables the precise and fast handling of large logs, significantly improving work safety

– allows a single operator to do everything safely from inside the excavator cab

Suddite features enable the entire production process to:

– be fast

– well done

– get significant cost relief

– reduce downtime

Safety Standards

They include:

– obligation of specific training for operators

– clear and visible signage on the worksite

– securing work areas

– use the PPE

– proportionate use of equipment according to weight, volume and power requirements

– checking the stability of the operating machine before starting work

– knowledge of procedures in case of emergency

Operators must be aware of the risks and strictly follow safety procedures, minimizing the danger of accidents and ensuring a safe operating environment for all.

In addition, it is very important to consult the manual. Learn the correct procedures in order to achieve optimal use of the equipment, including prohibitions on the product and accessories used with it.