FORESTRY EXCAVATOR GRAPPLE: HOW IT WORKS AND HOW TO CHOOSE IT

Wood grapples are essential equipment for those working in forestry, agriculture or construction. Mounted on an excavator, they make it possible to move logs, branches and other woody materials efficiently and safely. But how exactly do they work? And how to choose the right one for your needs? Let’s find out together.

The Operation

What exactly is a forestry grapple? Simply put, it is an extension of the operating machine arm designed to grab, lift and move woody materials of all kinds: logs, branches, brushwood, even whole trees. But how does it work?

The mechanism is based on a hydraulic system that operates two or more movable jaws called claws. The operator, through the excavator controls, can open and close the claws to grasp the material, lift it, transport it, and finally release it to the desired position.

There are different types of forestry grapples, each with specific characteristics suitable for different types of work:

– Two-clawed grapples The most common and versatile, ideal for medium and large logs.

– Multi-claw (or polyp) tongs Perfect for handling branches, brushwood and smaller materials because of their ability to adapt to irregular shapes.

– Combination grippers These grippers combine the functionality of a traditional gripper with that of a rotator, allowing the operator to rotate the gripped material for more precise positioning.

– Grapples with integrated saw These innovative grapples integrate a saw directly into the structure, allowing them to cut and handle material in a single operation.

Activating the excavator’s hydraulic system, the gripper jaws open ready to grip. Once positioned around the material, the jaws close firmly, gripping it tightly. The powerful excavator arm lifts up, taking the load with it to the desired location. With a simple command, the jaws open again, releasing the material gently and precisely.

How to Recognize a Quality Product

To identify a quality forestry grapple, it is important to consider a few key aspects:

– Materials of construction Verify that the clamp is made of high-strength steel and that the hydraulic components are of reliable brand.

– Manufacturing Precision A quality grapple has precise welds, well-aligned components, and a design that allows efficient operation of the claws.

– Warranty and service The presence of a comprehensive warranty and efficient service are indicators of a quality product.

THE QM Product

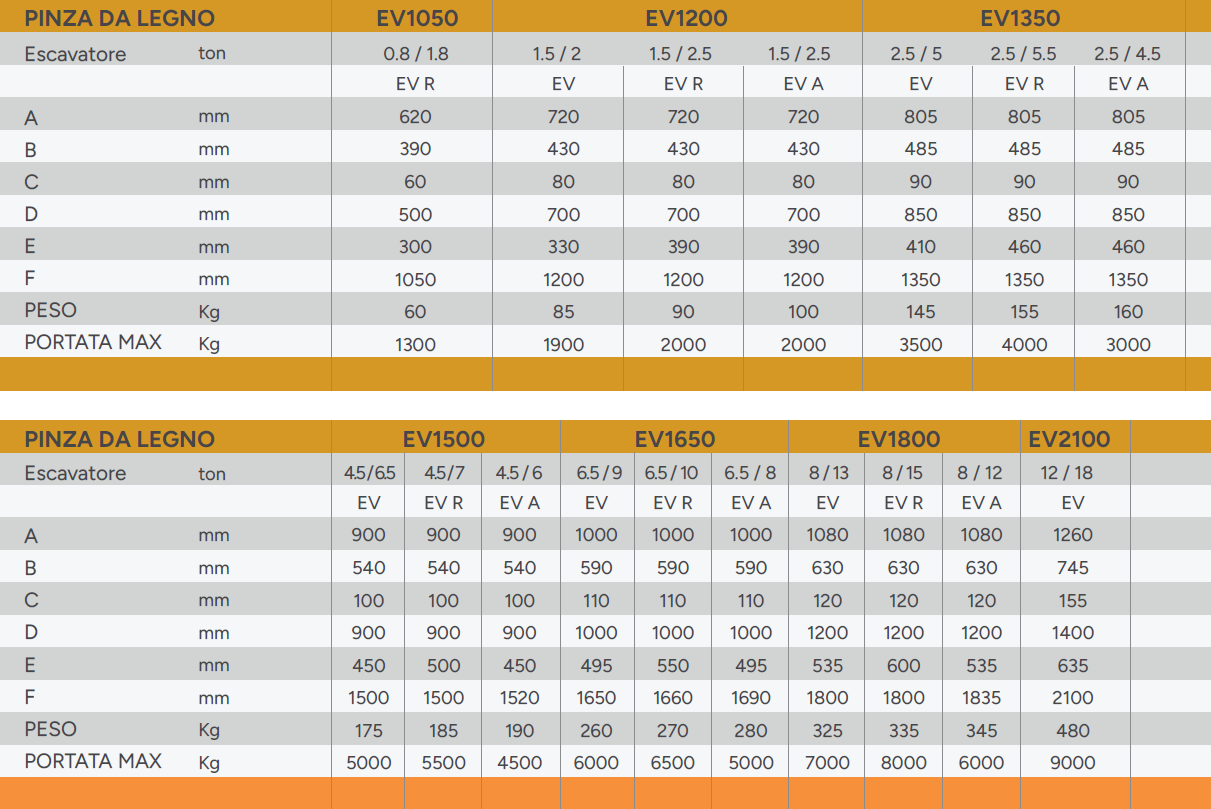

QM’s forestry grapple is the result of many years of study and field testing with industry professionals. It is manufactured from superior quality steel DOMEX 700 which gives it excellent strength and robustness ensuring a long-lasting tool suitable for any working scenario. Available in different versions distinguished by the ability to open the claws, this tool from QM is very performing, especially when installed on the operating machine of adequate operating weight. In fact, it is important to point out that, in order to use it effectively and in total safety, the Wood Pincer must necessarily be coupled with an excavator appropriate in size and weight. For example, a claw with an opening capacity of 1.5mt can be installed on a 50 Qli excavator. Otherwise, a claw that is too large on a lighter weight excavator or vice versa, a smaller opening claw on a too large excavator, can generate stability problems. For proper tool/machine matching, it is advisable to follow the directions in the table below

What the QM Excavator Grapple looks like

The instrument consists of three parts:

1. Mechanical connection or arrangement for connecting the Rotator

2. 360° Hydraulic Rotator

3. Wood clamp

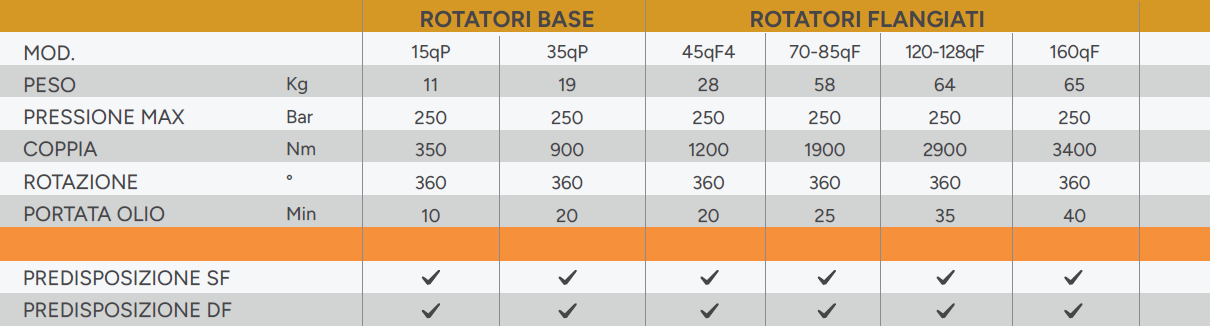

The Rotator is connected to the excavator’s hydraulic system by a gear specially prepared for the attachment. The QM Rotator allows the Grapple to be rotated at a full 360° angle. This component must also be proportioned to the excavator. For a proper Rotator/excavator combination, the following sheet can be consulted

The geometry of the claws is finely designed to have a precise and secure grip on the materials to be picked up and moved, managing to incorporate even portioned lumber and shorter and thinner branches. The design, which has been studied down to the smallest detail, enables accurate and effective grouping of timber.

In addition, the structure of the claw is composed, at the pivot points, of a number of bushings that make it possible to significantly decrease wear and tear, adequately lubricate the sensitive parts of the equipment, and drastically reduce the need for frequent maintenance. In addition, maintenance is facilitated by these arrangements thus being quick and less costly.

The advantages of a QM forestry grapple

Investing in a QM Agri forestry grapple means choosing a reliable partner that will stay with you over time, ensuring a quick and lasting return on investment. Thanks to their robustness, efficiency and ease of maintenance, this equipment will enable you to maximize productivity, reduce operating costs and increase the profitability of your business. A QM Agri forestry grapple is a tool that delivers high performance and an unparalleled customer experience.

The quality of manufacturing materials

DOMEX 700 steel is significantly superior to the materials from which such equipment is usually made; for example, the widely used S235JR steel is an unalloyed fine-grained structural steel that has good weldability and ductility but limited tensile strength. Domex 700, on the other hand, is a hardened and tempered high-strength structural steel and is suitable for use in construction and mining equipment. Cranes, Lifting Booms, heavy vehicles, and all applications requiring high strength are manufactured with this material.

Maintenance

Choosing a QM Agri forestry grapple means investing in a tool designed to last and simplify the operator’s work. Thanks to the bushings, positioned at the pivot points of the grapple, wear and tear caused by the constant movement and stresses to which it is subjected during work is drastically reduced. In addition, these components are easily lubricated, which results in easier, less frequent and, consequently, more economical maintenance. The user can spend less time on routine maintenance and focus more on productivity, without compromising the efficiency and durability of the tool. Reducing the frequency of maintenance not only optimizes working time, but also helps keep operating costs down, making the QM Agri forestry grapple an even better investment in the long run.

The assistance

Buying a QM Agri forestry grapple means entering a world where product quality is blended with impeccable customer service. The company stands out for its scrupulous attention to the customer, a value that translates into an unparalleled purchasing and after-sales experience.

From the very first contact, the customer is accompanied by a team of experts ready to provide personalized advice, guiding him or her in choosing the forestry grapple best suited to his or her specific operational needs. This sartorial care also extends to after-sales, with prompt and decisive service, providing peace of mind when using the equipment. QM Agri not only provides a high-quality product, but also establishes a relationship of trust with the customer based on expertise, availability and passion for their work. An added value that turns the purchase of a forestry grapple into a long-term investment, supported by a reliable and ever-present partner.