EXCAVATOR STUMP GRINDER: ULTIMATE GUIDE TO CHOOSING, USING, AND OPTIMIZING YOUR STUMP GRINDER

In gardening or reclamation works, when we cut trees and shrubs, stumps of various diameters remain stuck in the ground that are difficult if not impossible to eradicate. The Stump Cutter is useful for shredding the log left planted in the ground and extracting it safely without it remaining an obstacle for subsequent works to be done. A good device adapts to any type of wood and is versatile and precise in working thanks to the possible adjustments of the drilling depth. There are a variety of types and for all needs. The market offers self-propelled, stationary, and different sized cuttings.

The choice on the correct equipment to supply falls on several factors:

– Soil type

– Size of the stump

– Location where the shrub to be extracted is located

– Experience and skills of the operator

Often the workmanship requires intervention to be considered “surgical,” especially in certain environments such as urban areas. In streets or on sidewalks, it is necessary to work carefully in order to avoid damage to pipes and facilities. Same thing when reclaiming municipal green areas such as parks and villas. Using the Shredder therefore becomes crucial to achieve an excellent result. Easy to guess that the first step is definitely to choose the right Corkscrew Cutter.

Scope of operation

It is mainly used in the following areas:

– Construction, for preparing the surface for building

– Agriculture, for clearing new land, removing and grafting the new planting

– Urban green management, for eradicating stumps from roads, sidewalks and curbs

– Remediation of any area that needs cleaning, decorating and securing

– Maintenance of parks, gardens and municipal villas

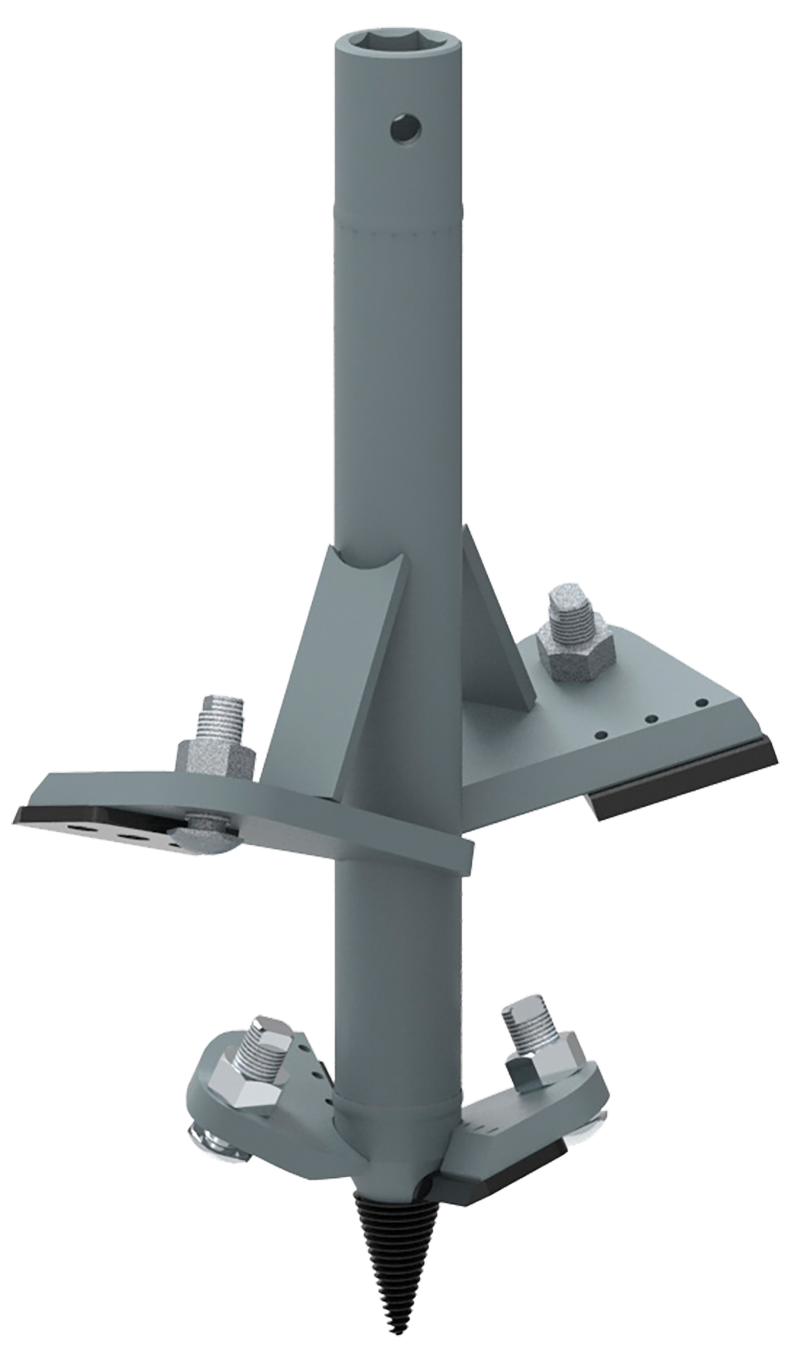

QM milling machine: main components and accessories

It employs substantial radial forces and loads. During work, the instrument is subjected to particularly intense stress, so it is important to use it with the TL HD Auger. The connection must be made in “locked” mode. Thus it operates with maximum efficiency thanks in part to HD support. Heavy Duty in fact, is ideal for this type of equipment. Users can choose any operating machine according to their needs.

The product

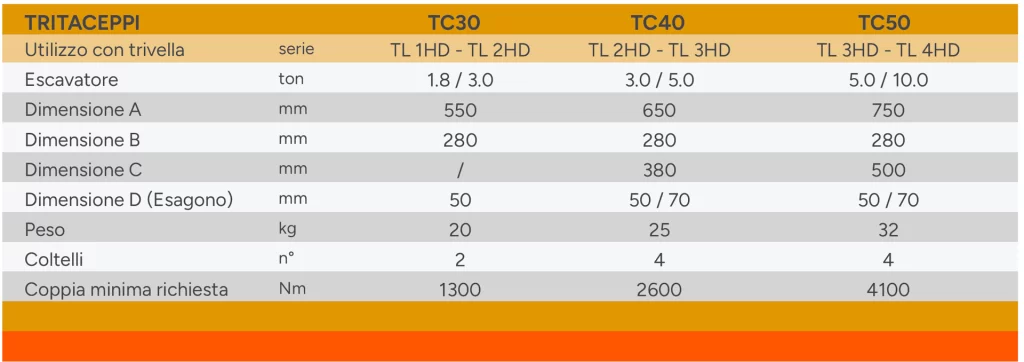

Available in three types differentiated by tool outer diameter:

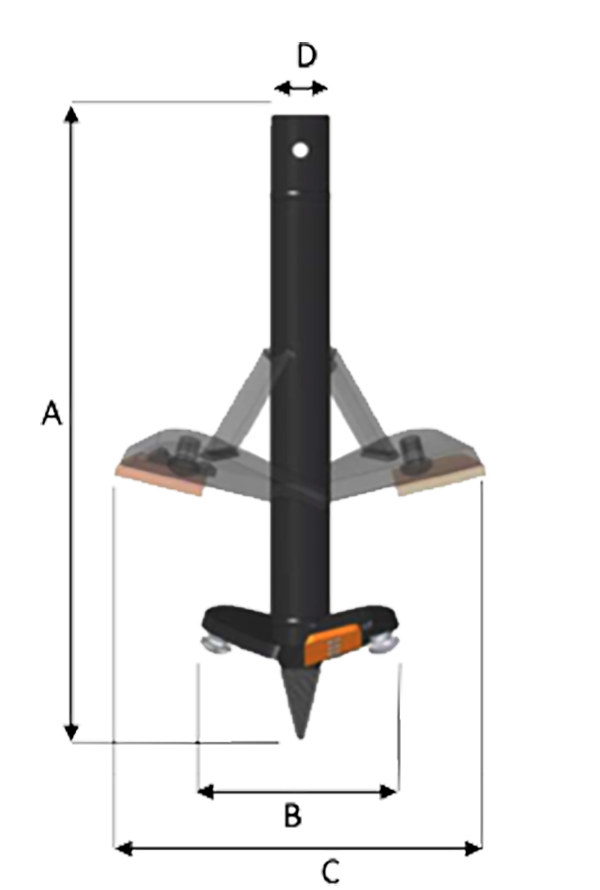

Dimensions refer to respectively:

– Total height of the accessory

– Diameter of the lower drilling bit

– Diameter of the upper drilling part of the tool

– Diameter of the hexagon of engagement

In addition:

– The weight reported in kilograms is that of the tool

– The type of excavator compatible with the tool version is differentiated by tonnage

– The minimum torque required refers to the operating machine motor

Installation and storage

The connection is very simple:

– Lubricate the inside of the hex bushing

– Oil the hex exit of the auger

– Engage the tool to the hydraulic auger via the hex connection

– Insert and lock the safety screw

The QM Crop Shredder has screws that limit and adjust the cutting depth of the blades. Proper parameterization of the stops is important for optimal operation.

To see if the setup is correct and suits the type of wood to be processed and the performance of the operating machine, it will be sufficient:

– Begin drilling the stump

– Do not exert excessive pressure

– Check that the Stump Cutter starts cutting steadily without stalling

If it should stall, the blade is probably “eating” too much material by pass. Adjust the screws/blades to take some grip off the knives. This is usually only done the first time if necessary.

Finishing the work is very important:

– Disconnect the Cork Shredder from the auger

– Thoroughly wash the attachment and rid it of debris

– Lubricate the inside of the hex bushing

– Store in a safe place protected from the elements

Useful tips

To always have the instrument efficient and operate safely, it is important to follow some simple rules:

– Check the stability and leveling of the operating machine before processing

– Clear the work area of obstacles or things that could be damaged

– Level the ground and ensure that safe distances are maintained

– Take timely action to make any repairs

– Use the Shredder only for purposes for which it was manufactured

– Avoid use in construction demolition

– Keeping the blades sharp

– Check the wear condition of the knives to maintain optimum performance and contain working time

– Do not force the tool sideways

– Do not apply too much pressure, but let the conical screw tip drag the blades toward the trunk

Strengths

Among the most relevant:

– Maintenance-free

– Blades manufactured from special steel with special heat treatment that increases their longevity and sharpness retention

– Optimizes processing time

– Speeds up the whole operation process

Suddite characteristics enable the entire production process:

– To be quick and accurate

– Well done

– Optimized costs

– Reduced downtime

Occupational Safety Standards

They include:

– Excellent skills and training in the use of the tool and operating machine

– Clear and visible signage on the work site

– Securing work areas

– Use of PPE

– Proportionate use of equipment based on weight, volume and power requirements

– Be careful of sharp blades when handling and maintaining attachment

– Keeping equipment in areas inaccessible to the public

– Knowledge of procedures in case of emergency

Operators must be aware of the risks and strictly follow safety procedures. Minimize the danger of accidents and ensure a safe working environment for all.

In addition, it is very important to consult the manual. Learn the correct procedures in order to achieve optimal use of the equipment, including prohibitions on the product and accessories used with it.