HOW DOES THE EXCAVATOR AUGER WORK?

The excavator auger is a precise and efficient tool that is widely used in various work sectors:

– Agriculture

– Construction

– Maintenance of vegetation

– Securing railways and roads

The auger enables drilling, land reclamation and maintenance, as well as multiple other uses. It is used to install poles or foundations in construction, while in agriculture it is valued for clearing undergrowth, grafting and safeguarding plantations, and maintaining and refining green areas. It is also widely used in the construction of fencing to secure specific areas.

Main components and accessories of the QM drill

The QM drill is composed of several parts that are essential for its proper functioning. The main elements include the hydraulic motor, planetary gearbox, power supply, and transmission that provide the power needed to operate the auger. It also includes a machine attachment for connection to the excavator and other important mechanical components described in the next section. QM drill accessories include:

– Stump and root sh redder – used to shred stumps rooted in the soil or roadway

– Concrete mixer – for mixing and transporting concrete

– Propeller drills – for rock drilling

– Propeller drills – for soil drilling

– Propeller drills – for drilling hard and stony ground

– Compaction propeller dr ills – for soil drilling and compaction

– Power harrow – for soil refining

– Splitting screw – for splitting large woody logs

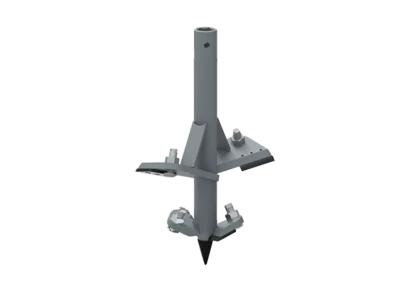

What the QM drill looks like

The auger is made of superior quality steel, ensuring heavy use and long service life. The cylindrical frame houses advanced mechanics and is attached via a specific machine attachment, also made of steel and adapted to the excavator being used. Major components include:

– Shockproof valve

– Reversing valve

– Planetary gearbox

– Flow reducer

– Steel crankcase

– Heavy Duty Support

Shockproof valve

Essential in very demanding contexts that require massive and continuous work, even of long duration. This component prevents damage to the motor in the event of tool blockage by managing excess pressure, which can occur, should one find oneself in very heavy work situations.

Reversing valve

Very useful in case the operating machine is one-way. In fact, with this system, it will be possible to recreate the optimal working conditions of a bidirectional machine by actually achieving tool rotation in both directions and the same performance. This system makes it possible to reduce time and workloads.

Planetary gearbox

It greatly increases the force by significantly reducing the revolutions of the hydraulic motor. It is used to increase power output and achieve high torque that the hydraulic motor would otherwise fail to accomplish on its own. It achieves this function through a reduction ratio by increasing power through a process that creates a difference in input engine speed.

Flow reducer

Important especially if the auger is used with Skid Loader type operating machines with high flow system as it avoids possible damage by managing and reducing oil flows when necessary. This prevents particularly harmful situations such as overspeeding and seizure of the hydraulic motor from occurring.

Steel crankcase

Made from superior quality steel, it protects the drill components. It also has excellent accessibility that makes it safe and quick to maintain all the mechanical parts stored inside.

Heavy Duty Support

A true flagship of QM, this component increases resistance to radial loads from lateral oscillations. It is essential in the use of attachments such as the cement mixer, splitting screw, and stump grinder that require particularly heavy and intensive workload.

Process of working with the QM drill

The tilling process begins with proper soil preparation to ensure effective and safe work. The QM auger, thanks to its machine attachment, allows it to work even in uneven situations. The machine attachment can be configured in two different modes depending on the type of work required:

- Rigid body – needed for accessories such as Stump Crusher, Log Splitter, Harrow and Concrete Mixer

- Joint – preferred for drill bits

During preparation, you place and install the attachment on the auger, making sure the auger is stable, firmly attached, and with the engine off. It is important to consider the conditions of the surrounding environment for optimal and safe work.

Maintenance and safety in the use of the Auger

Regular maintenance is essential to ensure proper operation of the auger and prolong its service life. It is necessary to check the condition of accessories, wear and tear of mechanical parts, and replace oils according to the instructions in the manual. Following safety regulations, you should always wear personal protective equipment and observe safe distances.

It is good practice to perform preventive maintenance, such as regular inspection of major components, thorough cleaning after each use, preventive replacement of wear parts, and constant updating of maintenance schedules. In addition, it is useful to keep track of the working hours of all equipment involved in order to schedule preventive maintenance work in a timely manner, reducing the risk of sudden failure and extending the useful life of all components.

Occupational safety standards

Occupational safety regulations for the use of excavator drills include:

– Mandatory specific training for operators

– Clear and visible signage on the worksite

– Securing of work areas

– Periodic inspection of equipment

– Use of PPE

– Knowledge of procedures in case of emergency

Operators must be aware of the risks and strictly follow safety procedures, minimizing the danger of accidents and ensuring a safe working environment for all. In addition, it is very important to consult the user manuals to learn the correct procedures, including prohibitions regarding the auger and accessories used with it.